From a simple brief to a Grand Design

The brief was simple: a large, luxurious in ground tiled pool that is cost effective to operate. Executing it was not quite so simple but as the pictures reveal, Hampshire pool dealer, Neptune Swimming Pools, with a little help from Certikin, achieved a fantastic result and a very satisfied customer! Neptune’s MD, Lee Campbell takes up the story…

“After receiving an email from a local building company, who we’d worked with in the past, an appointment was arranged to meet on site as it became clear that this wasn’t just another back yard liner pool install. The client’s request was simple but exacting – a large in ground fully tiled pool which was both luxurious and cost effective to operate.

“All was going well until we discovered that the site was on the very edge of the salt marshes and had a tidal water table, covering the area upon which the pool was to be sited. A specialist ground works team was engaged to provide constant dewatering for what seemed like a lifetime until the external walls of the basement and building were constructed and cured.

“The walls of the pool were then shuttered and cast in reinforced concrete.

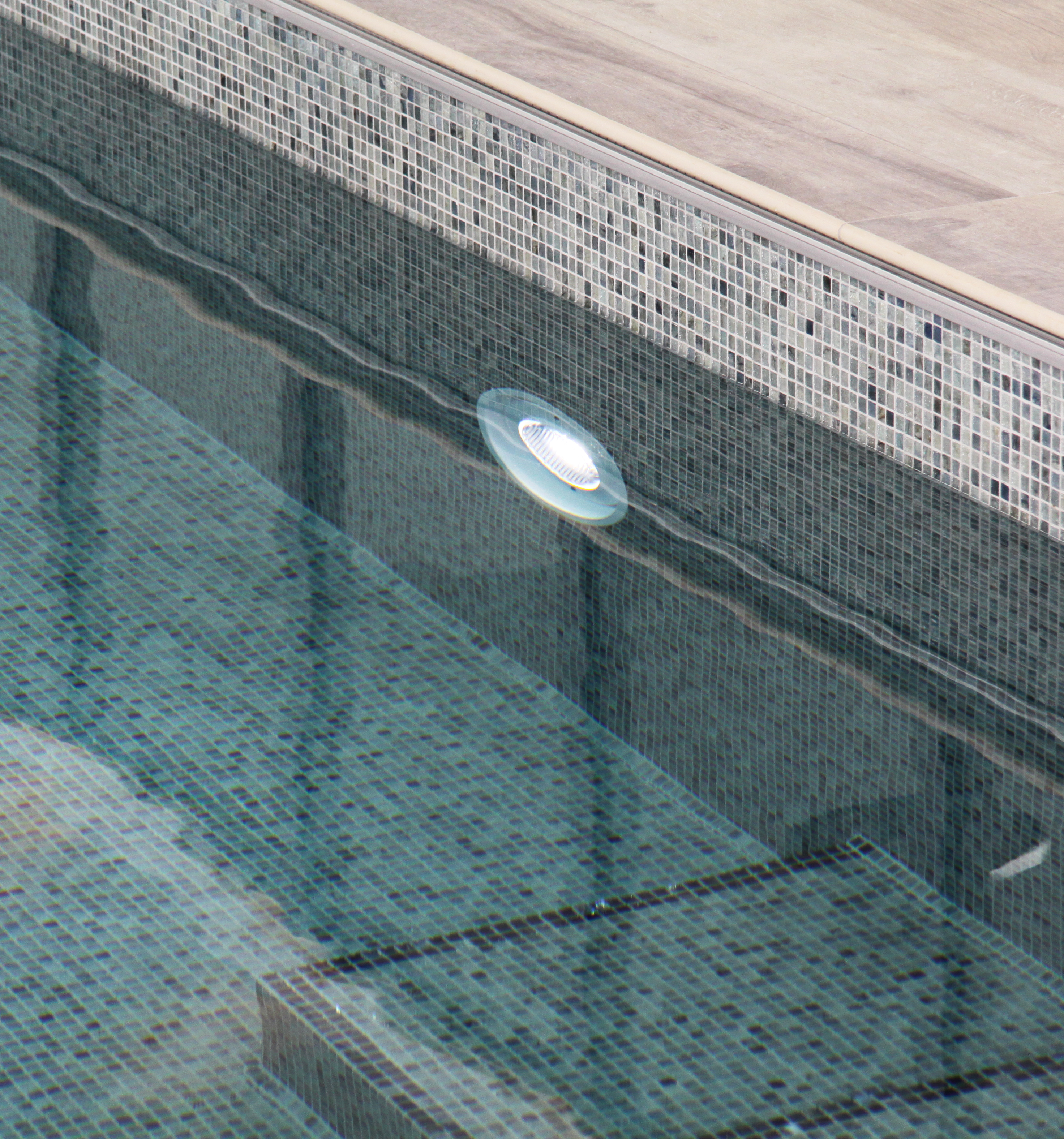

Standard white Certikin shell fittings were installed into the shuttering prior to the concrete pour. Flexi pipe work was run around the pool to the basement plant room. Certikin’s white LED lights were installed to compliment the pool hall’s other LED light systems.

“It was clear from the start that we would need a substantial environmental control system so the H&V team at Certikin were consulted and they suggested a Delta 6. The unit arrived on site and was duly craned into the plant room, where it sat for several months as bad weather prevented any progress on site.

“The client had chosen his own mosaic tiles and the pool was rendered out with internal steps at both ends and a bench constructed the entire length of the 15m x 5.5m pool. The pool depth was chosen at 1.40m with a flat bottom profile, so it could be used by all of the family and guests.

“An Aquaspeed pump and Vision filter with glass media were an obvious choice as we have used this equipment for several years with excellent results.

“After careful consideration, a Coverstar safety cover was commissioned with an in wall track system, housed in a pit at the back of one end, covered with heavy duty lid trays and extended brackets so the floor tiles could continue across the cover pit. The Certikin engineers were even able to reverse the boom, so it was set lower across the pool and therefore hidden when the cover was off the pool. Once the pool was filled, the Coverstar was installed and the system commissioned.

“Next, the Calorex engineer commissioned the Delta unit and the pool was up to temperature within seven days, with air temperatures and humidity settings being reached within the same time. To say I was impressed with the Delta is an understatement. As this was our first large indoor pool project, I had no hesitation in speaking to the Certikin team for advice and guidance which was very forthcoming.

“This project has been one of largest projects to date and to see it from humble beginnings to its completion has been both a headache (at times) and an absolute pleasure. I would like to pass on special thanks to Ryan Collins, in the Coverstar department for his patience, understanding and professionalism, especially with the client changing his mind several times at the eleventh hour.

“I would also like to thank everyone at Certikin for providing a one stop shop of first class products, backed up by its knowledgeable staff whose understanding when you need it most is always appreciated but not often thanked.”

.